Explore the key differences between Corten steel and regular steel, including their composition, durability, and weathering properties.

Understand how Corten steel’s unique alloying elements, such as copper and chromium, allow it to form a protective rust layer, making it more resistant to corrosion compared to traditional steel.

Discover why Corten steel is often chosen for architectural and outdoor applications, while regular steel may require protective coatings to prevent rust. Learn which type of steel is better suited for your project based on aesthetics, maintenance, and longevity.

What Is Corten Steel And How Is It Made?

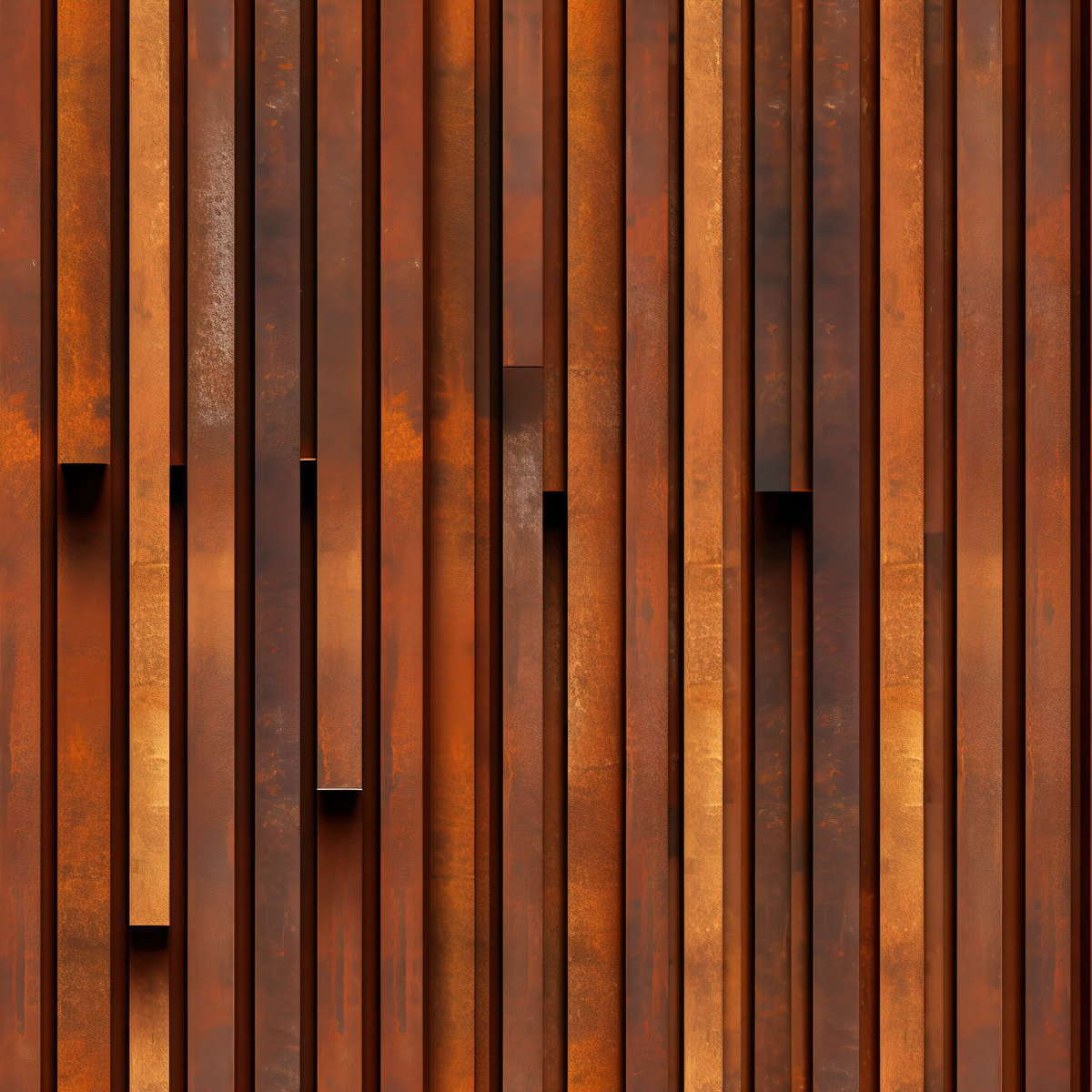

Corten steel, also known as weathering steel, is a type of steel alloy that is designed to form a rust-like appearance after being exposed to the elements over time. This steel is made by alloying it with other metals such as copper, chromium, and nickel. These elements help Corten steel develop a patina, which is a protective layer that prevents further corrosion.

Corten steel is created through a process similar to how regular steel is made. It involves melting iron and carbon along with alloying elements in a blast furnace. This mixture is then cast into slabs, which are rolled until they reach the desired thickness.

The chemical composition and alloying elements in Corten steel make it particularly resistant to weather and can last for many years with minimal maintenance. This makes it a popular choice for outdoor sculptures and building facades.

Corten Steel VS Mild Steel

Weather Resistance: Corten steel, also known as weathering steel, is much more weather-resistant compared to mild steel. When exposed to the elements, Corten steel develops a protective patina that shields it from damage. In contrast, mild steel requires regular painting or coating to prevent corrosion.

Extreme Temperatures: Corten steel performs better in extreme temperatures. It remains stable and doesn’t become brittle in cold or hot weather, unlike some mild steel products which may lose their strength.

Carbon Content: The carbon content in mild steel is typically low, making it a type of low-carbon steel that is softer and more ductile. Corten steel, however, is a low-alloy steel. It contains alloying elements like nickel and chromium for added strength and durability.

Maintenance and Treatment: Mild steel requires frequent maintenance and treatment to keep it from rusting. This means you need to paint or coat mild steel products regularly. On the other hand, Corten steel requires minimal maintenance due to the protective rust-like patina it develops when exposed to the elements.

Overall, the main difference between Corten steel and mild steel is their resistance to weather and the amount of maintenance required. Corten steel is more durable and weather-resistant but can be more expensive, whereas mild steel is more cost-effective but requires more upkeep.

What are the Uses of Corten Steel vs. Mild Steel?

Corten Steel: Corten steel is widely used in applications where durability and weather resistance are important. It is commonly used for building facades, bridges, and outdoor sculptures. The unique appearance of Corten steel, with its rust-like colour, makes it a popular choice for architects. It is also used in garden edging and landscape design for its strength and low maintenance needs.

Mild Steel: Mild steel is commonly used in construction and manufacturing. It is often used to produce structural components like beams, columns, and panels. Due to its lower cost, mild steel is a popular choice for projects that need large amounts of metal. It is also used in making everyday products like pipes, tools, and car frames.

You'll find that Corten steel is favoured for its weather resistance and unique appearance, making it ideal for outdoor and architectural applications. Mild steel, being more cost-effective, is widely used in construction and manufacturing where corrosion resistance is not as critical.

What Safety Precautions Should Be Taken When Using Metal Cutters?

When using metal cutters, certain safety precautions are essential to prevent accidents and injuries.

Wear Personal Protective Equipment (PPE): You must always wear PPE, such as gloves, safety glasses, and a welding helmet to protect yourself from sparks, heat, and harmful UV radiation. In doing this, you can shield your body from danger while carrying out metal fabrication and cutting tasks.

Ensure Proper Ventilation: Steel cutting generates fumes and gases that can be harmful if inhaled. Make sure you are working in a well-ventilated area or use an exhaust system to remove fumes from the workspace.

Check Your Equipment: Before you start working, check all the equipment to ensure it’s in good condition. Inspect the steel cutter, cables, and gas supply for any damage or leaks that could pose a risk.

Clear the Work Area: Next, you need to remove any flammable materials from the work area to prevent fires. Keep a fire extinguisher close by in case something ignites.

Follow Electrical Safety Rules: Metal cutters use high-voltage electricity. Make sure your equipment is properly grounded, and avoid standing in water or damp areas to prevent electric shocks.

By following these safety precautions, you can ensure a safer working environment when using a metal cutter.

What are Some Corten Steel Alternatives?

While Corten steel is valued for its weather resistance and unique appearance, there are alternatives that you might consider based on your needs.

Stainless Steel: Known for its high corrosion resistance and strength, stainless steel is a good alternative to Corten steel. It contains chromium, which helps produce a protective surface layer. Though it tends to be more expensive, it is highly durable and requires less maintenance.

Galvanised Steel: This type of steel is coated with a layer of zinc, which makes it corrosion-resistant. Galvanised steel is cost-effective and widely available, making it a popular choice for many applications. Yet, it might not have the same aesthetic appeal as Corten steel.

Aluminium: Aluminium is lightweight, corrosion-resistant, and easy to work with. It is commonly used in construction and manufacturing. While not as strong as steel, it is a great alternative for non-load-bearing structures.

High Carbon Steel: High carbon steel is another option, known for its strength and hardness. It doesn’t naturally resist corrosion like Corten or stainless steel but can be treated to improve its durability.

Weather-Resistant Paints and Coatings: If the appearance of Corten steel is what attracts you, but you need a cost-effective solution, consider using weather-resistant paints and coatings. These can help mimic the look of Corten steel while providing some level of protection against the elements.

By weighing factors like cost, maintenance, and aesthetics, you can find a suitable alternative to Corten steel that meets your specific requirements. Professional fabricators can provide you with more information on different types of steel and their applications. Get in touch with local specialists today to find out which material is best for your next project.

Contact us today if you are searching for corten steel fabricators near me. We offer corten steel fabrication for Colchester, Essex, London and Nationwide.