Learn how Corten steel is manufactured to achieve its unique weathering properties. Discover the process that combines specific alloys like copper, chromium, and nickel to create a durable material that forms a protective rust-like layer over time.

This manufacturing technique enhances the steel’s resistance to corrosion and eliminates the need for painting or maintenance.

Explore the detailed steps involved, from alloy selection to controlled oxidation, that result in Corten steel’s iconic look and long-lasting performance, perfect for architectural and outdoor applications.

What is corten steel and how is it made?

Corten steel, also known as weathering steel, is a type of low-alloy, high-strength steel that develops a protective patina layer when exposed to the elements. The alloying elements of corten steel include copper, chromium, and nickel. These metals give corten steel its unique corrosion resistance and tensile strength.

The manufacturing process of corten steel starts with raw materials like iron, carbon, and alloying elements such as copper, chromium, and nickel. These materials are melted together in a furnace to form the steel. After melting, the steel is cast into slabs, blooms, or billets, which are then subjected to a series of rolling operations to shape them into coils, plates, or sheets.

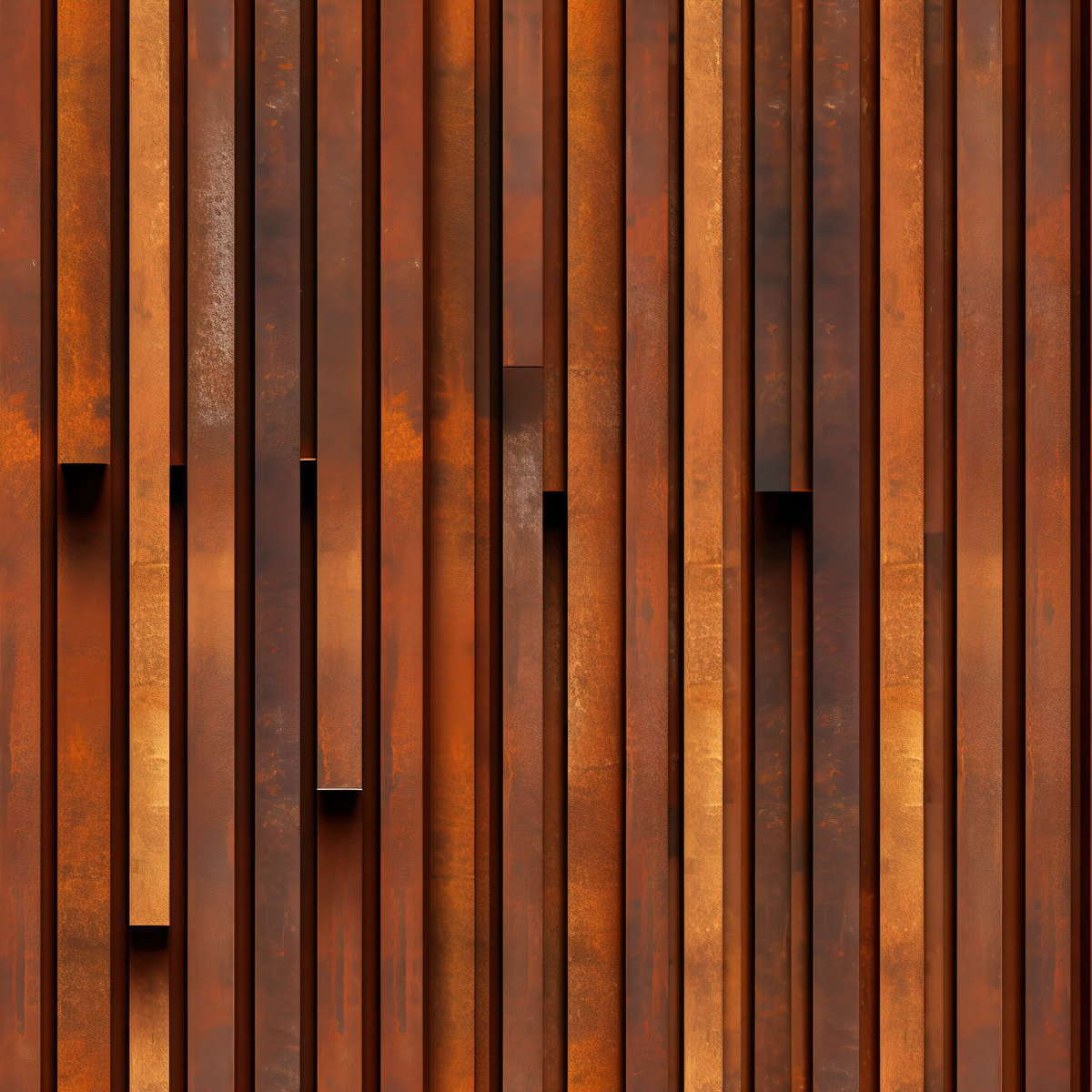

The steel is then allowed to develop its characteristic patina layer. This rust layer is essential as it forms a barrier that protects the material from further corrosion. The weathering process typically takes from a few months to several years, depending on environmental conditions. The final product is a corrosion-resistant, durable steel that does not need painting or other maintenance.

Pros & Cons of Corten Steel

Pros:

Durability: Corten steel is highly durable and provides long-lasting performance. It develops a protective layer of rust that prevents further deterioration. This makes it ideal for various applications like construction, art installations, and landscaping, ensuring reliability and minimal maintenance.

Anti-Corrosive: The protective patina layer offers excellent corrosion resistance, eliminating the need for painting. This natural layer forms gradually, providing long-lasting protection. It reduces maintenance costs and enhances the material's durability, making it a highly effective solution for various applications.

Highly Weather Resistant: The steel is designed to withstand a wide range of environmental conditions, making it ideal for various applications. Whether in construction, industrial settings, or for home use, this steel offers durability and reliability in both extreme and everyday situations.

Aesthetics: The rust layer gives corten steel a rustic and artistic look. This makes it popular in architecture, sculptures, and landscaping. Over time, corten steel forms a protective layer through oxidation, which enhances its durability and weather resistance. This unique characteristic makes it a preferred material for outdoor and industrial applications.

Low Maintenance: Once the patina layer has developed, corten steel requires minimal maintenance. This unique protective layer helps to prevent further corrosion and provides a distinctive, rustic appearance. It is resistant to the elements and can endure harsh weather conditions. Regular inspections and occasional cleaning will ensure its longevity and aesthetic appeal.

Cost-Effective: Corten steel is known for its impressive durability, making it a smart choice for many projects. Due to its long lifespan and low maintenance needs, corten steel can be cost-effective over time. Its resistance to weathering and corrosion also means it retains its aesthetic appeal for many years.

Protective Surface Layer: This layer prevents atmospheric corrosion, reducing the rate of deterioration. It acts as a barrier, shielding the underlying material from moisture and oxygen. By blocking these elements, it minimises the risk of rust and wear. This protection is essential to prolonging the lifespan and maintaining the integrity of the material.

Environmentally Friendly: Corten steel is 100% recyclable and requires fewer resources over its lifetime. This durable steel naturally forms a stable rust-like appearance when exposed to weather, which protects it from further corrosion. As a result, it has a long lifespan and reduces the need for maintenance or extra protective coatings.

Cons:

Staining: During the initial weathering process, corten steel can stain nearby structures. This happens because the rusty patina it develops sheds small particles that may wash onto surfaces. To avoid this, apply a sealant or position the steel away from areas that must remain clean, such as patios or walkways.

Climate Compatibility: In humid environments or where the steel is continuously wet, the protective layer may not form correctly, which can lead to increased corrosion and potential failures. This can compromise the structural integrity of the steel, necessitating frequent inspections and maintenance to prevent serious damage and ensure long-term durability.

Welding Techniques: Special welding techniques are required to ensure the quality and durability of the joints. These techniques include precise temperature control, proper material selection, and skilled handling by trained professionals. Adhering to these standards not only guarantees strong welds but also prevents potential failures.

Retention Traps: Corten steel can form water or moisture traps, which may hasten corrosion if not designed or placed correctly. To maintain its longevity, ensure proper design and placement. Regular inspection and maintenance can also help prevent the build-up of moisture, protecting the steel from premature rust and damage.

How much does Corten cost?

The corten steel cost can vary widely depending on size, thickness, and form. On average, corten steel may be more expensive than mild steel but offers benefits that justify the extra cost. The price can range from around £500 to £1000 per tonne. Plates or sheets of a specific size can be sold at a higher rate due to the higher demand and longer lifespan.

Costs can vary depending on suppliers and specific project requirements. For example, a specialised sculpture might need a higher corten steel grade, driving up the cost. While corten steel has a higher initial cost, its low maintenance and durability make it an economical choice in the long run.

What is Expanded Corten Mesh?

Expanded corten mesh is a form of corten steel that has been cut and stretched to create a mesh-like pattern. This product is commonly used in architectural designs, building façades, and outdoor installations due to its unique appearance and functional properties.

The process starts with a corten steel sheet, which is cut and pulled into a mesh. This mesh design helps in creating a network of evenly spaced holes. This mesh is then formed and shaped to meet specific design requirements. It offers a high strength-to-weight ratio and excellent corrosion resistance, making it suitable for a wide range of applications.

The expanded corten mesh develops the same protective patina layer as other forms of corten steel, ensuring durability and weather resistance. This makes it a popular choice for creative and functional outdoor structures.

Sealing & Maintaining Corten Steel

While corten steel is low maintenance due to its protective patina, there are instances where sealing might be necessary to ensure long-term performance. For example, sealing can help reduce staining during the patina development phase, especially when placed near stone or concrete structures.

A common method of sealing is to use a transparent sealant specifically designed for weathering steels. This sealant creates a protective barrier, reducing water contact while allowing the steel to continue its weathering process. It’s essential to apply the sealant evenly and cover all surfaces to ensure complete protection.

Regular maintenance of corten steel usually involves minimal tasks. It's crucial to inspect the steel periodically for any signs of abnormal wear or corrosion. In situations where corten steel is used in highly humid or wet environments, extra caution should be taken. Doing so ensures that the protective patina forms correctly.

For welded or joined sections, it’s important to use the correct welding techniques to maintain the steel's quality and durability. The use of compatible welding materials ensures that the welded joints also develop a protective layer.

Despite its low maintenance, corten steel can be influenced by its environment. So, understanding the local climate and taking appropriate measures will ensure that the steel remains in prime condition for many years.

Contact our corten steel fabricators today and see how we can help with your Corten steel needs in Colchester, Essex, London and Nationwide.